Cad systems

- NX CAD & CAM- Siemens

Data exchange formats

- STEP 3D

- IGES 3D

- DWG 2D

Simulation software

- Magmasoft 5.4

ERP

- SAP B1 HANA

MEASURE-TEST-DOCUMENT

Metal & Moulding Material

- Simulation Software- Magmasoft 5.4

- Thermo analysis

- Fully equipped Sand testing laboratory

- Metal Analyzer-Foundry Master Germany

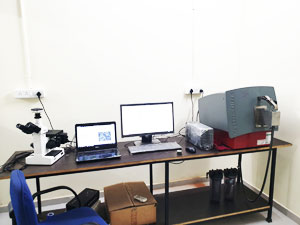

- Microscopy

- Density Index Analyzer

- Tensometer and Die coat thickness and viscosity tester

Physical properties

- Hardness testing

- Tensile testing

- X- ray testing

- Pressure test for leakage

- Ultrasonic testing

Measuring

- Zeiss Contura G2 CMM with scanning facility

- 3D scanner- GOM (Germany)

- Mahr Marsurf XC2 for contour measurement

- Mitutoyo SJ410 surface roughness tester

Tool support system

- Shrink Fit Machine-Haimer (Germany)

- Tool Pre Setter – Zoller (Germany)